An Integrated Supporting System including the Upper process for Mechanical Desig n and Manufacturing Process

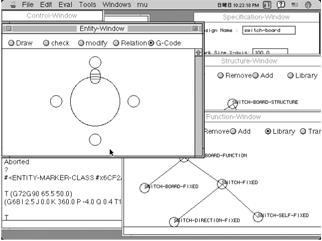

Recently, many design-supporting systems have been used in the area of NC machi ne production. However, designers have been using those systems as only a "drawi ng tool" because most of them can support only a special design framework of a p articular phase, for instance proofreading a design and generating NC code, in the overall design process. Their frameworks are useful for the lower process. T he current systems have not treated a support for the upper process. Then design ers must take two styles of design framework: a framework which designers have t o deal with and a computer-aided-framework, together at the same time. In our research, our conception of design is transformation from a function spa ce to a structure space. Our system describes function features, structural fea tures and entity feature of designed objects. We propose a flexible supporting system for design frameworks at all phases of the design process. In this paper, we propose a new design supporting system for NC machine producti on including a support for the upper process. We explain this system's concept a nd the method that we used for implementing of the system.

Research Papers:

- Hideaki KANAI: A Study on a Framework for Supporting Design and

Manufacturing Process and its Application to NC Machining, Ph.D. Thesis,

University of Electro-Communications, Tokyo JAPAN(1998-3) (in Japanese)

- Hideaki KANAI, Nobukazu WAKABAYASHI and Hakaji HONDA:

An Integrated Supporting System Including the Upper Process for

Mechanical Design and Manufacturing Process,

Journal of IPSJ, Vol.36ˇ¤No.8ˇ¤pp.1926-1937 (1995-8)(in Japanese)

- Hideaki KANAI, Nobukazu WAKABAYASHI and Hakaji HONDA: An Integrated System for Mechanical Design and Manufacturing Process of NC Machi ning using Object Oriented Methodology, 27th International Symposium on Automoti ve Technology and Automation (ISATA), Proceedings for Dedicated Conference on Me chatronics, pp.335-342 (Nov. 1994)

A Nesting System for NC Machining Using Structural Features of Parts

The layout problem has been examined in many different fields such as VLSI, plant and windows of GUI layout design. However, it is known to be NP-complete and therefore it is not possible to provide exact solutions. This research addresses a packing problem of NC (Numerical Control) machining called the nesting problem. The problem is to allocate as many parts as possible in a certain area. The solution is essential to increase NC machining productivity. There are many applications to propose techniques to the solution and they have contributed to the improvement of productivity. However, they tend to concentrate on the problem of packing rectangular shapes, have to treat a new part as its maximum rectangular area, and can not use the past nesting results easily. In this paper, we propose a solution based on structural features of parts, and show the effectiveness using a nesting system based on our methodology. In our system, we adopt CBR (Case Based Reasoning) including mechanism of approximating structure of parts to recognize their structure. The recognized parts are classified into five types of shape by the structure features, and then for parts of each type, the local positions are decided. Finally, the parts are placed globally on an area.

Research Papers:

- Hideaki KANAI, Nobukazu WAKABAYASHI and Hakaji HONDA:

An Integrated Supporting System Including the Upper Process for

Mechanical Design and Manufacturing Process,

Journal of IPSJ, Vol.36ˇ¤No.8ˇ¤pp.1926-1937 (1995-8)(in Japanese)

Hideaki's Home Page