Mechanical Properties of Molybdenum Disulfide Nanoribbons with Armchair Edges

Researchers measured the Young's modulus of these nanoribbons as a function of their width, revealing interesting insights

The properties of nanoribbon edges are important for their applications in electronic devices, sensors, and catalysts. Recently, a group of scientists from Japan and China studied the mechanical response of single-layer molybdenum disulfide nanoribbons with armchair edges using in situ transmission electron microscopy. They showed that the nanoribbon Young's modulus varied inversely with its width below the width of 3 nm, indicating a higher bond stiffness for the armchair edges.

Sensors have become ubiquitous in the modern world, with applications ranging from detecting explosives, measuring physiological spikes of glucose or cortisol non-invasively to estimating greenhouse gas levels in the atmosphere. The primary technology required for sensors is a mechanical resonator. Traditionally, quartz crystals have been used for this purpose owing to their high rigidity and easy availability. However, this technology has recently given way to advanced nanomaterials. One such promising material is the single-walled molybdenum disulfide (MoS2) nanoribbon.

Characterizing the physical and chemical properties of nanoribbon edges is crucial for their applications in electronic devices, sensors, and catalysts. However, the mechanical response of MoS2 nanoribbons--expected to be dependent on their edge structure--has remained unexplored, hindering their practical implementation in thin resonators.

Against this background, a group of scientists from Japan and China, led by Professor Yoshifumi Oshima from Japan Advanced Institute of Science and Technology (JAIST), has recently investigated the mechanical properties--namely the Young's modulus--of single-layer MoS2 nanoribbons with armchair edges as a function of their width using a micromechanical measurement method.

Their work, published in the journal Advanced Science, was co-authored by Associate Professor Kenta Hongo and Professor Ryo Maezono from JAIST and Lecturer Chunmeng Liu and Lecturer Jiaqi Zhang from Zhengzhou University, China.

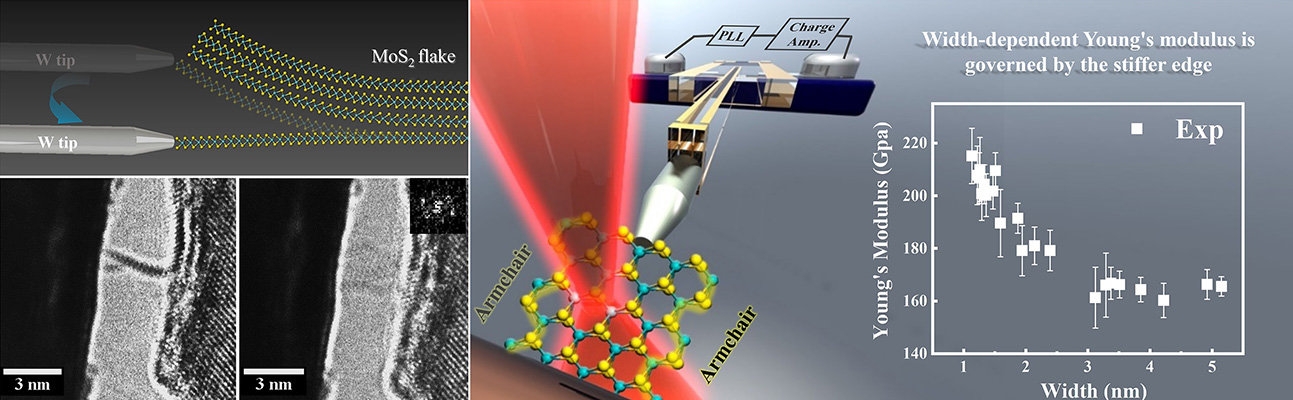

Prof. Oshima describes their work in detail: "We have developed the world's first micromechanical measurement method to clarify the relationship between the atomic arrangement of atomic-scale materials and their mechanical strength by incorporating a quartz-based length extension resonator (LER) in an in situ transmission electron microscopy (TEM) holder." Since the resonance frequency of a quartz resonator changes when it senses contact with a material, the equivalent spring constant of the material can be estimated with high precision by the change in this resonance frequency. Moreover, it is possible to capture high-resolution TEM images as the LER vibration amplitude necessary for the measurement is as small as 27 pm. Consequently, the novel method developed by the researchers managed to overcome the shortcomings of conventional techniques, achieving high-precision measurements.

The researchers first synthesized a single-layer MoS2 nanoribbon by peeling off the outermost layer of the folded edge of an MoS2 multilayer using a tungsten tip. As a result, the single-layer nanoribbon was supported between the multilayer and the tip. The TEM image of this MoS2 nanoribbon revealed that its edge had an armchair structure. "The width and length of the nanoribbon were also measured from the image, and the corresponding equivalent spring constant was determined from the frequency shift of the LER to obtain the Young's modulus of this nanoribbon," elaborates Lecturer Chunmeng Liu.

The researchers found that the Young' modulus of the single-layer MoS2 nanoribbons with armchair edges was dependent on their width. While it remained constant around 166 GPa for wider ribbons, it showed an inverse relation to the width for ribbons below 3 nm in width, increasing from 179 GPa to 215 GPa as the nanoribbon width decreased from 2.4 nm to 1.1 nm. The researchers attributed this to a higher bond stiffness for the edges compared to that of the interior.

Moreover, density functional theory calculations performed by the researchers for explaining their observation revealed that the Mo atoms buckled at the armchair edge, which resulted in electron transfer to the S atoms on both sides. This, in turn, increased the Coulombic attraction between the two atoms, enhancing the edge strength.

This study thus sheds important light on the mechanical properties of MoS2 nanoribbons, which could facilitate the design of nanoscale, ultra-thin mechanical resonators. "Nanosensors based on such resonators can be integrated into smartphones and watches, which will enable people to monitor their environment as well as communicate the sense of taste and smell in the form of numerical values," concludes an optimistic Lecturer Jiaqi Zhang.

Image Title: Mechanical properties of single-layer MoS2 nanoribbons investigated using a new micromechanical measurement method

Image Caption: (Upper left) Illustration showing the process of contacting a tungsten (W) tip to the edge of MoS2 multilayer and peeling off the outermost single-layer MoS2 nanoribbon. (Lower left) TEM image of the single-layer MoS2 nanoribbon observed from the cross-section and from the plane. (Middle) schematic illustration of the in situ TEM experiment on the nanoribbon with armchair edges, and (right) Young's modulus of the nanoribbon as a function of its width.

Image Credit: Yoshifumi Oshima from JAIST

License Type: Original Content

Usage Restrictions: Cannot be reused without permission

Reference

| Title of original paper: | Stiffer bonding of armchair edge in single-layer molybdenum disulfide nanoribbons |

| Authors: | Chunmeng Liu, Kenta Hongo, Ryo Maezono, Jiaqi Zhang*, Yoshifumi Oshima* |

| Journal: | Advanced Science |

| DOI: | 10.1002/advs.202303477 |

| Publication Date: | 11 September 2023 |

Funding information

This study was supported by JSPS KAKENHI (Grant Nos. 18H01825, 18H03879, and 23H002255), the China Scholarship Council under Grant No. 201808050001 and the support of the Sasakawa Scientific Research Grant from The Japan Science Society (No. 2021-2011), the Sasakawa Scientific Research Grant from The Japan Science Society (No. 2020-2006) and the Exchange Research Grant Project from Marubun Research Promotion Foundation.

September 19, 2023